About: Electric meters, depending on the size of electricity (amperage) being measured, can be either transformer rated or self driven. For amperage lower than 200 amperes, self driven meters are generally used where the electricity being consumed passes through the meter. For higher amperages, current transformers or CTs are used coupled with a meter to measure consumption.

CT cabinets, an important component of an electricity distributing system, encase the current transformers or CTs which are utilized for electricity metering. A form of electrical enclosure, CT cabinets perform the dual role of safeguarding users from live parts of the system as well as protecting the transformers they encapsulate from harsh conditions.

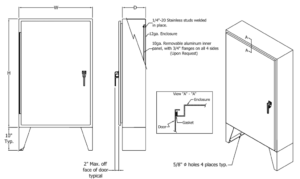

CT cabinets are generally made from carbon steel, galvanized iron or stainless steel. The use of steel enables the cabinet to be used as an earthing  system in certain transformer set-ups. To shape the cabinet, fabrication methods including cutting and welding are utilized. Powder coating is electrostatically applied to the cabinet walls which creates the main protective barrier against several external elements. The powder has a mix of epoxy and polyesters which protect the cabinet from chemicals, solvents, extreme weather as well as scratches. The interior section of the cabinet generally has a pre-fabricated mounting frame to enable the transformers to be mounted either vertically or horizontally. The cabinet can be an indoor or outdoor unit depending on the location and size of transformers.

system in certain transformer set-ups. To shape the cabinet, fabrication methods including cutting and welding are utilized. Powder coating is electrostatically applied to the cabinet walls which creates the main protective barrier against several external elements. The powder has a mix of epoxy and polyesters which protect the cabinet from chemicals, solvents, extreme weather as well as scratches. The interior section of the cabinet generally has a pre-fabricated mounting frame to enable the transformers to be mounted either vertically or horizontally. The cabinet can be an indoor or outdoor unit depending on the location and size of transformers.

Types & Ratings: In line with their numerous applications, CT cabinets can be classified based on their type of mounting – wall-mounting, pad-mounting or free-standing which depends on the nature and size of transformers. Moreover, another dimension of classification is the nature of the cabinet’s access point or door– screw cover, lift-off cover, hinged screw, hinged double door as well as the vented double door.

When it comes to the safety rating of CT cabinets, two standard setting bodies, Underwriters Laboratories (UL) and National Electrical Manufacturers Association (NEMA), have designed a rating scale of the harshness of external conditions that the cabinet can endure. In order to get a particular certification for a cabinet, the manufacturer is required to successfully test the product under the specified rating conditions.

When it comes to the safety rating of CT cabinets, two standard setting bodies, Underwriters Laboratories (UL) and National Electrical Manufacturers Association (NEMA), have designed a rating scale of the harshness of external conditions that the cabinet can endure. In order to get a particular certification for a cabinet, the manufacturer is required to successfully test the product under the specified rating conditions.

When it comes to current transformer cabinets, the common NEMA standards NEMA Type 1, NEMA Type 3R and NEMA Type 4X. Cabinets of all three ratings provide adequate protection to workers from inadvertent access to hazardous components. In terms of equipment protection, a NEMA Type 1 electrical cabinet is the lowest on the protective scale, is only specified for indoor use and protects the transformers from dirt and similar particulate matter. A NEMA Type 3R electrical cabinet can be used either indoors or outdoors and provides protection from dirt, water (including rain, sleet and snow) and is expected to withstand the formation of ice on the cabinet body, if used outdoors. The NEMA Type 4X electrical cabinet is of a higher rating to the Type 3R; it incrementally provides greater corrosion protection to the transformers as well as protection against hosed directed water.