Types, Fabrication, Uses

In the modern world the use of equipment and machinery that are both efficient and cost effective is a must to be competitive in business. In the electrical and electronics discipline, the modern world has seen the development of standards that define the recommended specifications of electronic components. These standards are well expressed in the Current Transformer Cabinets (CT Cabinets), whose importance in the today’s digital world cannot be underestimated.

Types of Current Transformer Cabinets

CT Cabinet types include but not limited to Type 1, Type 2, Type 3, Type 3R, Type 4, Type 4X, Type 6, Type 12 and Type 13. However, different standards organizations, commonly the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories Inc (UL) have different standards on how they rate each of the CT Cabinet types. NEMA does not require testing of the CT Cabinets by independent qualified inspectors and, therefore, the quality compliance obligation is entirely left to the manufacturers. On the other hand, UL under UL 50 and UL 508 requires testing of the manufactured CT Cabinets by an independent specialist to ascertain whether they meet the set quality standards and specifications.

CT Cabinet types include but not limited to Type 1, Type 2, Type 3, Type 3R, Type 4, Type 4X, Type 6, Type 12 and Type 13. However, different standards organizations, commonly the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories Inc (UL) have different standards on how they rate each of the CT Cabinet types. NEMA does not require testing of the CT Cabinets by independent qualified inspectors and, therefore, the quality compliance obligation is entirely left to the manufacturers. On the other hand, UL under UL 50 and UL 508 requires testing of the manufactured CT Cabinets by an independent specialist to ascertain whether they meet the set quality standards and specifications.

Fabrication

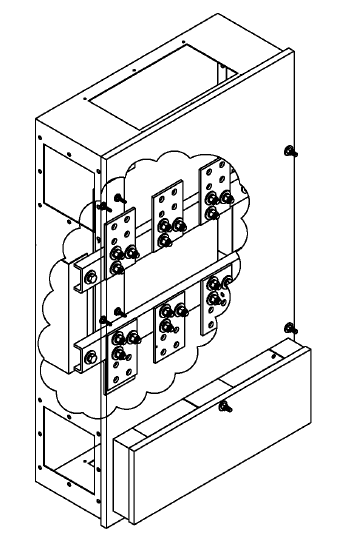

Whichever standard is followed; the CT Cabinets are the end products of metal fabrication that is achieved through various processes such as bending, welding and cutting among others. A typical NEMA Type 3R CT Cabinet fabrication would result in features such as an overlapping double-door cabinet that has lift-off hinges and 3-point latch; door-stop provision inclusion; removable copper bars and mild steel hinges. However, different CT Cabinet manufacturers have different metal fabrication process to produce distinct designs of the same type. For instance, the manufacturers of NEMA Type 3R CT cabinet or UL Type 1R cabinet may decide to either use overlapping double-door designs for large cabinets or still use a single-door model. In this sense, the metal fabrication process determines the quality and general outlook of the final CT Cabinet produced. Conformance with the NEMA and UL regulations, therefore, require the manufacturing companies to ensure their Metal Fabrication processes are aligned with the expected standards and specifications by the quality control bodies. The CT Cabinets are usually fabricated from galvanized or heavy gauge steel.

Whichever standard is followed; the CT Cabinets are the end products of metal fabrication that is achieved through various processes such as bending, welding and cutting among others. A typical NEMA Type 3R CT Cabinet fabrication would result in features such as an overlapping double-door cabinet that has lift-off hinges and 3-point latch; door-stop provision inclusion; removable copper bars and mild steel hinges. However, different CT Cabinet manufacturers have different metal fabrication process to produce distinct designs of the same type. For instance, the manufacturers of NEMA Type 3R CT cabinet or UL Type 1R cabinet may decide to either use overlapping double-door designs for large cabinets or still use a single-door model. In this sense, the metal fabrication process determines the quality and general outlook of the final CT Cabinet produced. Conformance with the NEMA and UL regulations, therefore, require the manufacturing companies to ensure their Metal Fabrication processes are aligned with the expected standards and specifications by the quality control bodies. The CT Cabinets are usually fabricated from galvanized or heavy gauge steel.

Uses of CT Cabinets

Type 3R is one of the common CT Cabinets recommended by NEMA. Generally, CT Cabinets are made for indoor purpose, outdoor purposes, or both. The cabinets are specifically made to:

Ensure high personal protection against the enclosed transformer’s hazardous parts.

Protect the enclosed transformer against harmful effects of water ingress as well as protect the enclosed equipotent against windblown dust, falling dirt and other solid objects.

Ensure the enclosed current transformer is not damaged by ice formation on the external surface.

Such an aspect makes NEMA Type 3 CT Cabinets favorable for use in both outdoor and indoor electrical and electronic activities. UL Type 1 is another highly useful CT Cabinet, and which is equitable to NEMA Type 1. This type of cabinet is made to provide a certain degree of protection to people against incidental contact with the enclosed current transformer and also protect the equipment against dust and other solid objects. Essentially, both NEMA and UL tend to have a relatively similar rating on the different types of CT Cabinets.