An electrical enclosure is a hutch for electrical paraphernalia to keep displays, knobs, wiring and switches. It is used for protecting the electronics from the surroundings and to also reduce the risk of electric shock to the users.

There are standards used to categorize electrical enclosures based on their performances and use. In the USA, the two bodies that publishes these classes of enclosures are called the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL). NEMA and UL Ratings are assigned based on the functions and materials used in the construction of enclosure types. They are broadly defined by their usage in non-hazardous locations and hazardous locations.

For the purpose of this article, we will refer to the NEMA Types. A full comparison of NEMA and UL types can be viewed here.

Hazardous Locations

The hazardous locations may be commercial or industrial settings as defined in the National Electrical Code (NEC) where explosive chemicals, dust, or liquid may be present. At all times, these explosive agents may only be present during irregular activities, or only when components or processes fail.

They are classified from NEMA Types 7-10.

Non-Hazardous Locations

In these environments, there are no combustible substances in the environment.

NEMA Type 1: These are made for use indoors and they give a little protection to the users from the live parts. They typically come equipped with a latching door. One of the drawbacks is the unavailability of a gasketed sealing surface.

NEMA Type 3R: These types of enclosures are commonly used outdoors for junction boxes and wiring. Their construction creates protection for users against harmful components. The body of the enclosure is capable of preventing harm to the equipment from outside damages like sleet, external ice formation, falling rain, and snow. Indoor protection makes sure that dripping water will not be able to affect the equipment.

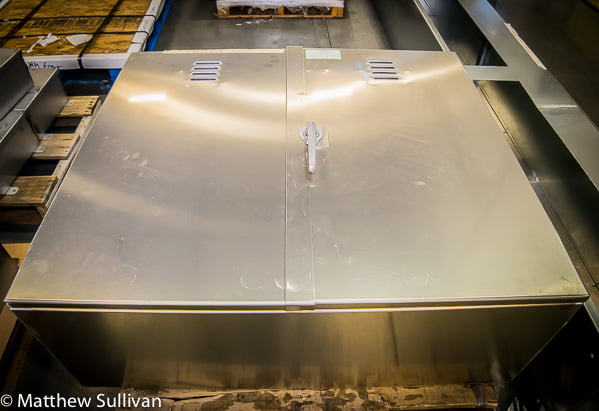

NEMA Type 4: This enclosure has a powder coating with carbon steel because it is suited for outdoor use. It is best for a location where pressurized streams of water or machine tool cutter coolant will be used and where there will be periodic washdowns. These are usually gasketed with a clamped door equipped which ensures a maximum seal.

NEMA Type 4X: These are used in harsh surroundings and for applications where corrosive materials such as caustic cleaners are used for it. Facilities that are ideal for this enclosure type include poultry/meat processing and petrochemical areas/offshore petroleum sites. It offers protection to users against dangerous parts. To provide adequate protection of the equipment from hazards such as foreign objects or water of various forms (hose directed water, sleet, rain, splashing water, and snow) a strong material is used for construction. The construction material used for it can be aluminum, polycarbonate, fiberglass, or stainless steel.

Others include NEMA Types 2, 3, 3S, 3X, 3RX, 3SX, 5, 6, 6P, 12, 12K, and 13.