Electrical utility installations require an interface between primary transmission system and secondary circuits. Whenever one electrical system interconnects with another, terminal cabinets are used. The common standards terminal enclosures must meet are:

● UL Type 1 – cabinets meeting this standard are intended for indoor use primarily as they are designed to protect users against accidental contact with live parts, as well as from falling dirt.

● NEMA Type 3R – cabinets falling within this classification are ideal for outdoor use and will provide protection against light rain and sleet. The cabinet should be of such construction it can withstand ice or snow collecting on the cabinet.

● UL 1773 – is the Standard of Termination Enclosures provided by Underwriters Laboratories so specify the safety aspects of termination cabinets.

The rest of this article discusses the different types of termination cabinets, their uses and applications as well as the metal fabrication techniques used to construct the cabinets.

The Different Types of Termination Cabinets

Termination boxes come in different sizes to suit the different applications. The cabinets also have several optional features which you can request if you are looking for a custom cabinet. UL Type 1 and NEMA Type 3R enclosures are suitable for both indoor and external applications and fall into the following groups:

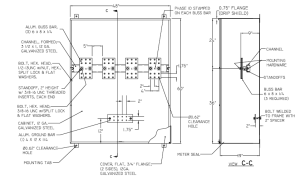

● Wall mounted termination enclosures.

● Pad mounted termination cabinets.

● Lay-in busbar termination enclosures.

● Cable splicing enclosures.

The various types of termination enclosures make them a versatile product to use for different applications. The UL Type 1 and NEMA Type 3R cabinets are suitable for both indoor and outdoor use which is another benefit of termination enclosures.

Applications and uses of termination cabinets

Termination cabinets are used in different industries, from power distribution to telecommunications. The purpose of termination enclosures is to house the interface between two wiring systems. For example, in electrical power distribution systems, engineers use termination cabinets to separate primary circuits into secondary circuits. Termination enclosures are also used as junction boxes for solar farms for marshalling all the DC cabling from the solar panels. They are also used by Electricity and utility companies for these purposes.

Metal fabrication processes for termination cabinets

Termination cabinets are constructed to meet UL Type 1, NEMA Type 3R and UL 1773 standards (UL 1773 is the standard for termination boxes). Termination boxes should be rated 600V or less to meet the UL 1773 standard. The most common construction materials are:

● Aluminium.

● Stainless steel.

● Mild steel.

● Non-metallic polycarbonate.

Advanced metal fabrication methods are used in the construction of termination enclosures, including laser cutting, metal forming and continuous seam welding. These methods contribute to the water and dustproof properties the enclosures exhibit, which makes them withstand challenging environmental conditions. Enclosures are made from 12 gauge and 14 gauge steel and then finished with powder coating, louvers and custom cut-outs as optional extras. Depending on specific applications, termination cabinets can also be specified with aluminium or copper bussing.